At Valfonta, the manufacturing of pressure reducing valves is a specialty in which we have years of accumulated experience, allowing us to guarantee the superior quality of our products. We are committed to providing customized solutions that meet the needs of each customer, working with a wide range of fluids, including steam, liquids, and gases.

Steps to design a pressure reducing valve

Before anything else, the following aspects must be taken into account when the time comes to choose the design of a pressure reducing valve:

Related Posts:

European regulations for designing pressure valves

To begin with, it should be noted that the existing regulation in America (ANSI) is not the same as what we have in Europe (EN). Consequently, we will show you everything related to European regulations.

On May 7, 1997, under Royal Decree 769/1999, the Pressure Equipment Directive, 97/23/EC, was published in the Official State Gazette (BOE). This directive establishes the minimum requirements that all equipment subject to a maximum allowable pressure PS greater than 0.5 barg 1 must meet regarding its design, manufacturing, and conformity assessment.

On the other hand, it is essential to know what type of substance will pass through the valve (vapor, liquid, or gas). Furthermore, it should be highlighted that these components have been classified into two completely differentiated types of fluid. Group 1 corresponds to hazardous fluids such as explosives, toxic substances, or oxidizers. In Group 2, the rest of the less harmful fluids are found.

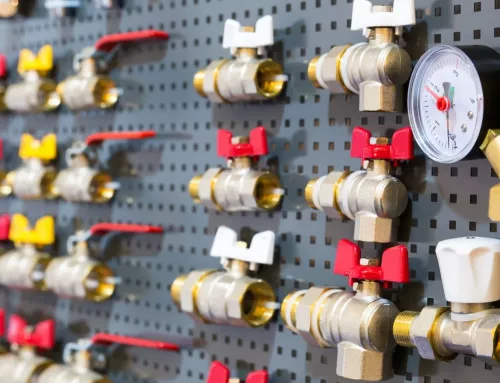

Our pressure reducing valves

For any questions or clarifications, contact our commercial department

If you have doubts or need additional clarifications, our commercial department team is always available to provide the assistance you require.

In the field of engineering and industrial manufacturing, a precise understanding of technical terms and specifications is crucial. We are aware that, given the complexity and use of specialized vocabulary in our sector, it can be challenging to understand exactly what is needed and what is being acquired.

At Valfonta, we not only strive to produce the highest quality valves but also dedicate ourselves to offering comprehensive and personalized advice to our clients.

If you need assistance in designing a pressure relief valve that perfectly suits your needs, you just have to fill out our form. Once we receive your request, we will get in touch with you as soon as possible to provide you with a detailed and personalized guide, ensuring you understand every aspect of the selected product.

Moreover, if you prefer more direct communication, you can contact us by calling 933 720 888. Our team of experts is always ready to assist you, answer your questions, and guide you through the selection and design process of your pressure relief valve. You can also email us at valfonta@valfonta.com, where we will respond to your inquiries with the same attention and efficiency.

At Valfonta, we are committed to providing exceptional customer service, ensuring that each interaction is informative, effective, and satisfactory. We are here to help, and we are delighted to address all your doubts and inquiries!

Leave A Comment