What do we offer at Valfonta?

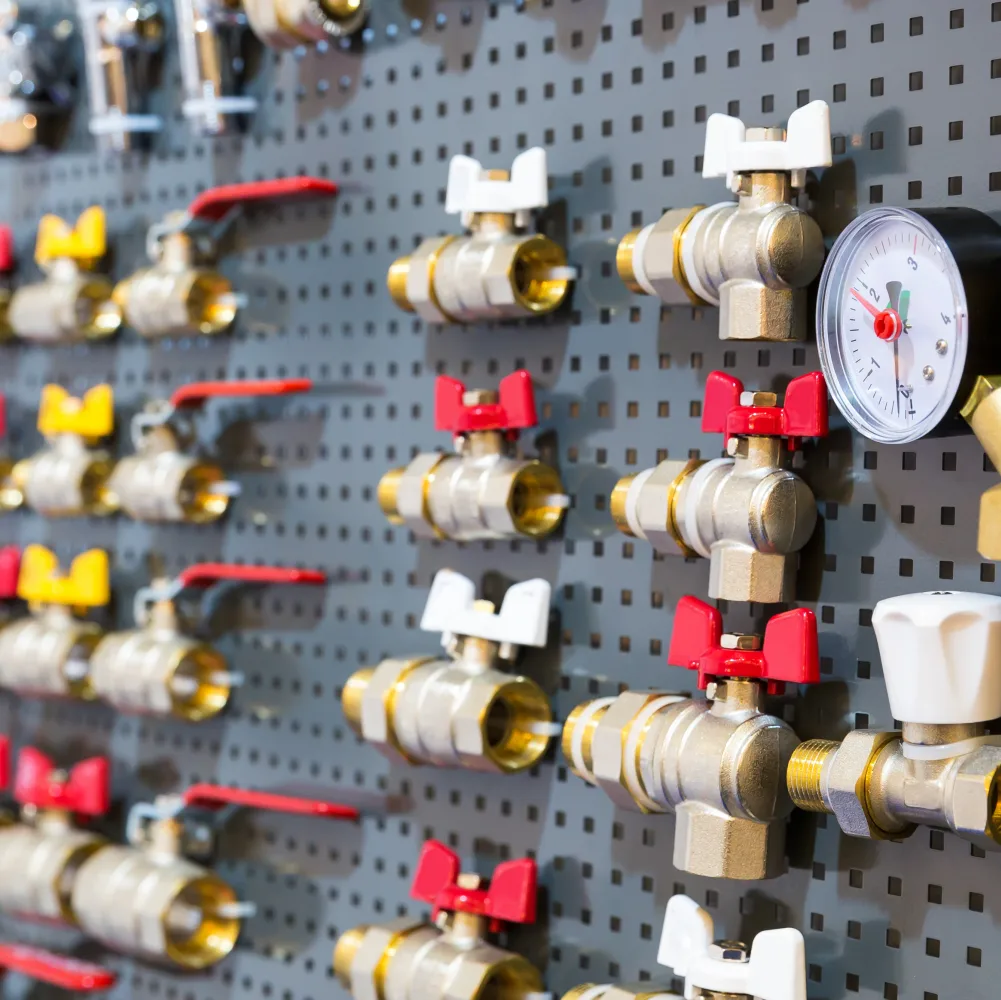

In the management of hydraulic and pneumatic systems, control valves play a crucial role in ensuring efficiency and safety.

In this post, we will explore the different types of control valves available on the market and provide detailed recommendations from Valfonta, a leading company in the design and manufacture of these devices.

We will also highlight the pneumatic actuator control valve from Valfonta, an advanced solution for various industrial applications.

Table of contents

- What do we offer at Valfonta?

- What is a control valve?

- Types of Control Valve

- Pressure reducing valve PRV30

- Pressure reducing valve PRV44

- Pressure reducing valve PRV45

- Pressure reducing valve VD

- Recommendations for selecting control valves

- Control valve with pneumatic actuator from Valfonta

- Common applications of control valves

- Contact us

- Our relief and pressure relief valves

What is a control valve?

A control valve is a mechanical device used to regulate the flow of fluids, whether liquids, gases, or steam, within a piping system. These valves allow adjustment of the flow rate, pressure, and temperature of the fluid, ensuring precise process control. Their operation is based on modifying the opening of the fluid passage using a movable element, which can be a disc, a ball, a diaphragm, among others.

Control valves are essential in applications where a quick and precise response to changes in system conditions is required, such as in chemical plants, refineries, and heating and cooling systems.

Types of Control Valve

Globe control valves

Globe control valves are a popular choice due to their simple design and ability to provide precise flow control.

These valves feature a movable disc that sits on a fixed orifice, allowing for the adjustment of the amount of fluid passing through the valve. They are ideal for high-pressure and high-temperature applications and are common in the oil and gas industry as well as in steam systems.

Butterfly control valves

Butterfly valves are known for their compact design and ease of operation. They use a disc that rotates on a central axis within the valve body to regulate flow.

This type of valve is ideal for applications where quick and frequent flow control is required and is commonly used in HVAC systems and water treatment.

Ball control valves

Ball control valves are known for their ability to provide tight sealing and ease of operation. They use a perforated ball that rotates within the valve body to control flow.

They are suitable for applications requiring low pressure drop and precise flow control, and are often found in high-pressure and high-temperature systems, as well as in oil and gas applications.

Diaphragm control valves

These valves use a flexible diaphragm to regulate flow and are ideal for applications requiring precise and leak-free control.

They are particularly useful in systems handling corrosive or high-purity fluids, such as in the pharmaceutical and food industries. Their design allows for easy maintenance and long service life.

Needle control valves

Needle valves are known for their ability to provide very precise flow control due to their thin stem design. They are ideal for low-flow, high-precision applications, such as in laboratories and dosing systems.

These valves allow for fine adjustments in flow rate, making them suitable for applications requiring meticulous control.

Three-way control valves

Three-way valves allow flow control in two different directions and are commonly used in blending or diverting applications.

They are ideal for systems that require flexibility in flow direction, such as in heating and cooling systems, where it’s necessary to divert or blend fluids to maintain optimal operating conditions.

Related articles:

Some of our most demanded valves:

Recommendations for selecting control valves

Control valve with pneumatic actuator from Valfonta

Valfonta offers a range of control valves designed to meet the most demanding needs of the industry.

A standout product is the pneumatic actuator control valve, which combines the robustness of Valfonta valves with the precision of a pneumatic actuator.

Characteristics of the control valve with pneumatic actuator

Common applications of control valves

This valve is ideal for a wide range of industrial applications, including the chemical, petrochemical, pharmaceutical, and food industries. It is particularly useful in systems that require precise control of flow and pressure to ensure safe and efficient operation.

Do you need personalized advice on our control valves?

Control valves are essential components in fluid systems management, and choosing the right type is crucial to ensure efficiency and safety in these systems.

Valfonta offers a wide range of high-quality solutions, including our pneumatic actuator control valve, which combines precision, reliability, and ease of maintenance.

By considering key factors in control valve selection, users can ensure optimal performance and extend the lifespan of their systems.

Feel free to fill out our contact form with your details to address any questions you may have about our control valves. We’ll be happy to assist you with personalized advice.