Valves designed to relieve pressure and guarantee the safety of the system and users against a potential fire

In this post we will try to clarify and explain in detail all of the characteristics of the fire protection pressure relief valves, also called Relief Valves.

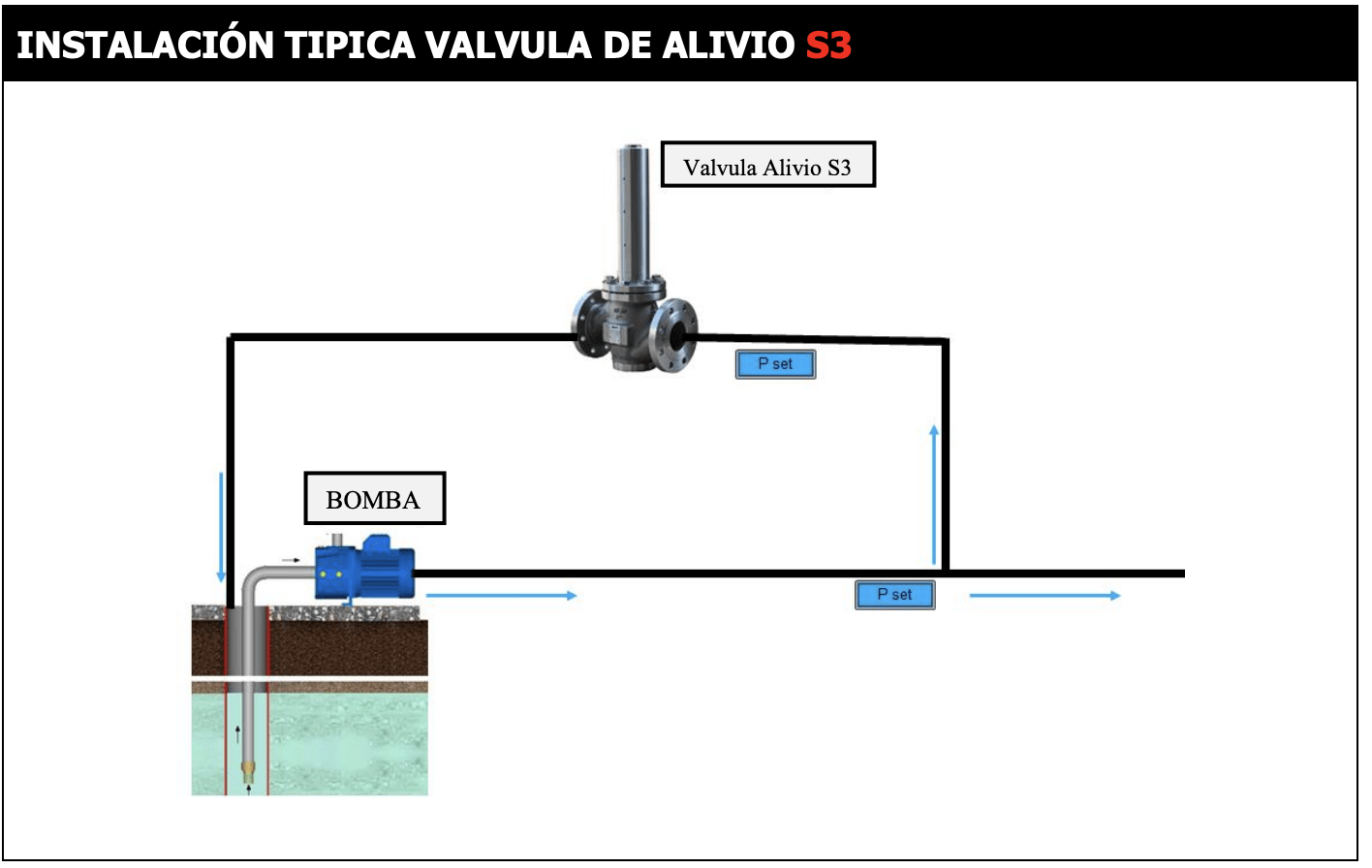

These valves are installed to prevent overpressure on a system or installation, when the pump reaches 110% of the working speed of the motor or, in other words, 121% of the churn or shut off pressure of the pump – a term used to refer to the pressure at 0 flow of the valve-.

Its main function is to prevent an overpressure in the fire protection system caused by the excess speed.

Our fire protection pressure relief valves: the S3 model

The S3 fire protection pressure relief valve works using the principle of direct action. This is when the resultant force of the inlet pressure exceeds the spring setting force, the valve opens proportionally to the pressure change- this spring force is adjusted using a special adjusting screw installed on the valve-.

In a model regulated by the ISO 9001 quality system; it should be handled, transported and stored with care. It is vitally important to protect the valve from external and adverse agents such as dirt, humidity and extreme temperatures.

It is important to remember that the valves may be too heavy to be moved manually, which is when suitable fixings should be used for the lifting equipment. It is not advisable to attach them to the delicate parts of the valve such as, for example, adjusting screws.

Other interesting characteristics to mention about this fire protection pressure relief valve are that the interior is manufactured in AISI 316L stainless steel, it has a guided plug to achieve greater stability of the flow, a set pressure that ranges between 0.5 and 20 barg, and is suitable for liquids, gases- from groups 1 and 2- and steam.

Furthermore, to control the set pressure the cap should be unscrewed, the O-ring should be removed carefully and the adjustment stem turned clockwise to increase the set pressure, or anti-clockwise to reduce it.

For these reasons, at Valfonta we always advocate that this valve should be installed by specialist personnel, with sufficient knowledge and experience regarding current regulations, to be able to quickly identify the risks that the entire process may entail. For example, a crucial point lies in ensuring that the valve and actuator never exceed the operating pressure and temperature that they can withhold.

Don’t hesitate to ask us for personalised advice in choosing your fire protection pressure relief valve or any of our other components

We have spent many years working as manufacturers of pressure relief, pressure reducing, control or safety valves. We also have a specific line of steam and liquid ejectors and injectors.

These types of components, if you do not understand aspects such as their mode of operation, terminology or their technical applications, can be difficult to choose between.

To receive direct and personalised advice from one of our specialist technicians, you just need to complete our contact form. You can also call us by telephone on 933 72 08 88 or send us an email to valfonta@valfonta.es.

We will answer all of your queries, provide you with detailed and valuable information and guide you throughout the selection process. This is, undoubtedly, one of the most important parts of our day-to-day work.

Leave A Comment