What is the function of the industrial steam injector?

The main function of industrial steam injectors is to increase the temperature of water or other liquids in a tank or boiler system. The injector aspirates the cold liquid, mixes it inside with the steam and distributes it heated throughout the tank, ensuring that its temperature remains high and stable at all times. On the other hand, it is important to mention that it is also possible and common to connect different injectors in parallel to achieve higher flow rates.

Main characteristics of the industrial steam injectors developed by Valfonta

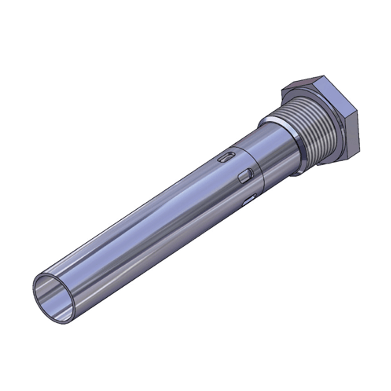

Valfonta’s industrial steam injectors have been specially designed to increase the temperature of any liquid. In essence, the injection piece sucks the liquid to be heated through its orifices, mixing with the steam and managing to increase its temperature. This causes a constant recirculation within the tank, which favors and guarantees both a good mix and the same temperature throughout the installation.

On the other hand, it is worth mentioning that it has no moving parts, a factor with which a significant reduction in noise and vibrations is achieved during periods of activity or operation. We are dealing with industrial steam injectors made of 316 stainless steel, of quality and full guarantees.

How to install this type of industrial steam ejectors?

It is recommended that this type of injectors are always installed in a horizontal position; it is important that there is no other element installed in the injector discharge area. If we want to avoid noise or vibration problems, the L dimension should be as long as possible, have the holes clean and without obstructions.

If the intention is to install 2 or more steam injectors, it is important that these are centered and installed in series, but there must always be a certain distance between the wall and the first injector.

Need help or want to ask us a question about industrial steam injectors?

Flow control valves and injectors are components that, if not well understood, can raise a long list of questions when it comes time to choose or install them. At Valfonta we have been dedicating ourselves to its manufacture for many years and a very important part of our work consists in listening to our customers, guiding them and advising them so that they always make the best decisions and decide on the components that are most suitable.

If you have any questions or need help from us, please do not hesitate to contact us. You can do so by writing an email to valfonta@valfonta.com, by calling +34 933 720 888 or by filling in the form that you will find on this website.

On the other hand, you can also come visit us at our facilities in Badalona, located on Carrer Bronze 26, within the Les Guixeres industrial estate, we will welcome you with open arms!

Leave A Comment