Industrial steam ejectors play a crucial role in numerous industrial processes that require vacuum generation or fluid handling. These efficient and versatile units utilize the principle of steam flow to generate suction and transfer energy. In this article, we will explore in detail the operation of industrial steam ejectors, their various applications, and the benefits they offer in industrial environments.

What are industrial steam ejectors?

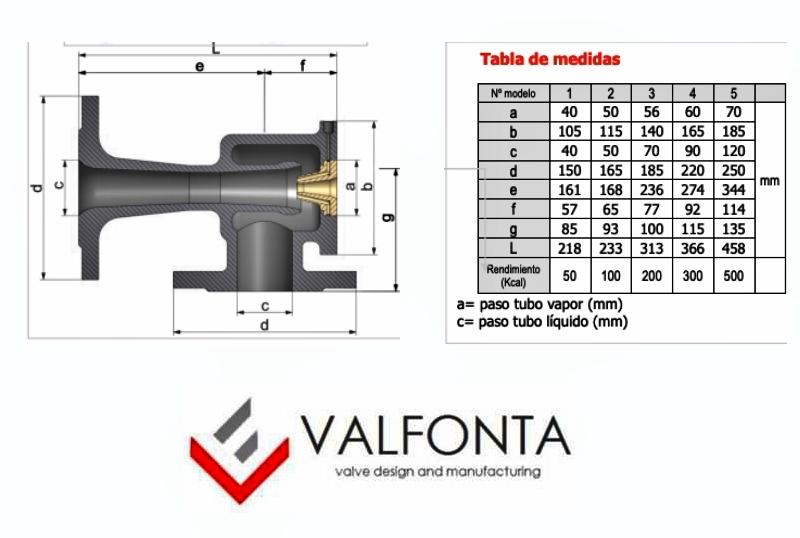

Industrial steam ejectors are devices designed to harness steam flow and generate vacuum or induce fluid circulation.

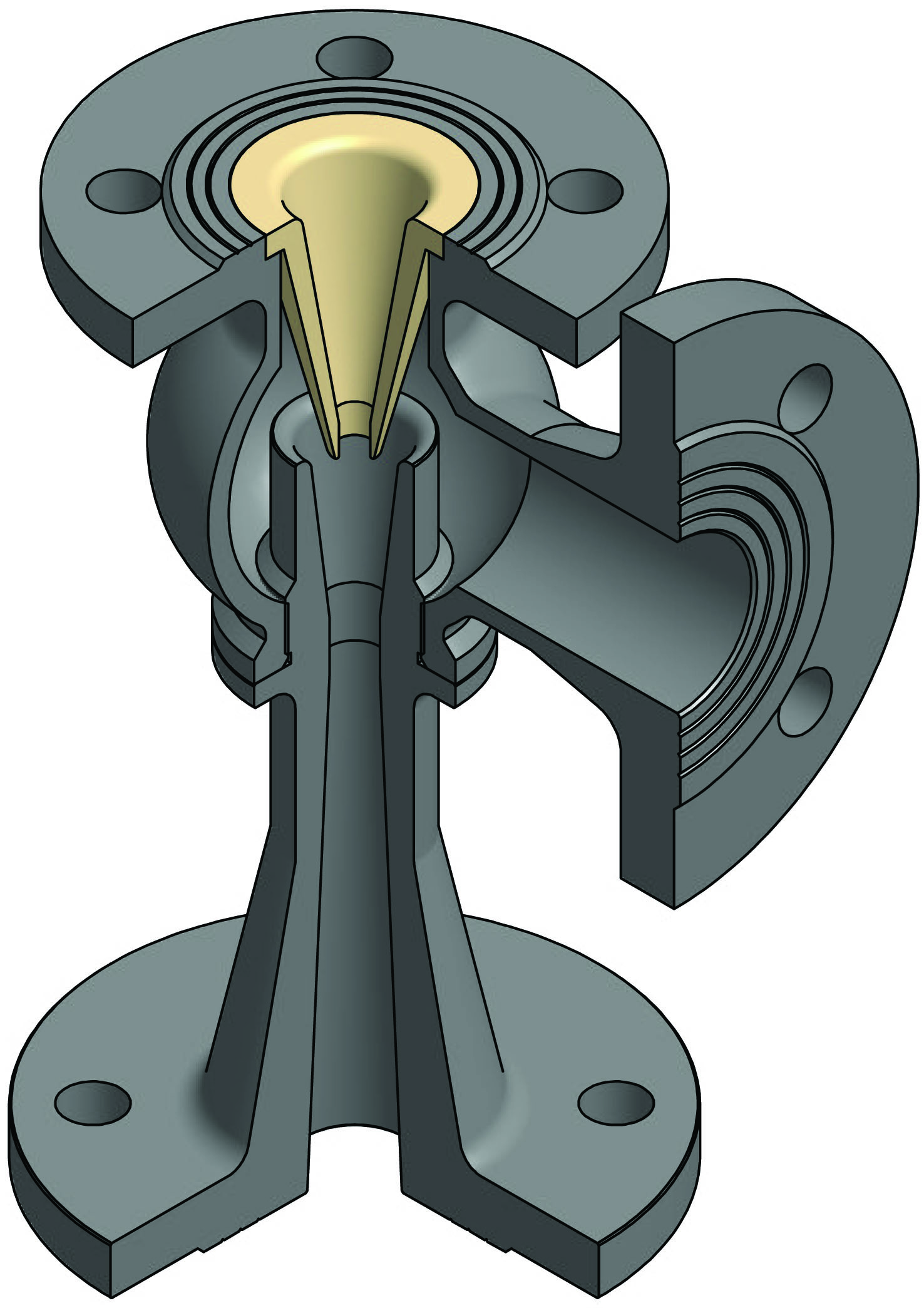

They consist of a series of nozzles, diffusers, and mixing chambers that, when interacting with steam, create a low-pressure zone that suctions the desired fluid.

These ejectors are known for their high energy efficiency and their ability to handle a wide range of fluids, including gases, liquids, and solids.

Operation of industrial steam ejectors:

Industrial steam ejectors operate based on the principle of fluid convergence-divergence. High-pressure steam is introduced through a converging nozzle, which increases the steam velocity.

As the steam accelerates, a low-pressure zone is created in a mixing chamber or diffuser, which in turn induces the fluid flow towards the ejector. This suction is the result of the pressure difference between the inlet and the low-pressure zone, allowing for fluid handling and transfer in industrial processes.

Applications of industrial steam ejectors:

Industrial steam ejectors find applications in a wide variety of industries and processes. Some examples of these applications include:

These are just a few examples of the many applications where industrial steam ejectors play a crucial role in production processes.

Benefits of industrial steam ejectors:

Industrial steam ejectors offer several benefits that make them an ideal choice for numerous applications in industrial environments:

Request information without obligation about our industrial steam ejectors

Choosing this type of component can be somewhat difficult if you do not know its applications, materials or operation perfectly.

If you have any questions regarding our products or services, do not hesitate to contact us by calling (+34) 933 720 888, sending an email to valfonta@valfonta.com or filling in the form that you will find on this same website.

We always like to finish by reminding that our specialty is the design of pressure reducing valves, being able to manufacture them to measure for each application. We also have an extensive catalog of pressure relief valves and control valves at your disposal. That being said…what exactly do you need?

Leave A Comment